Index

ToggleEnsuring HPP Integrity with rPET Cold‑Press Bottles

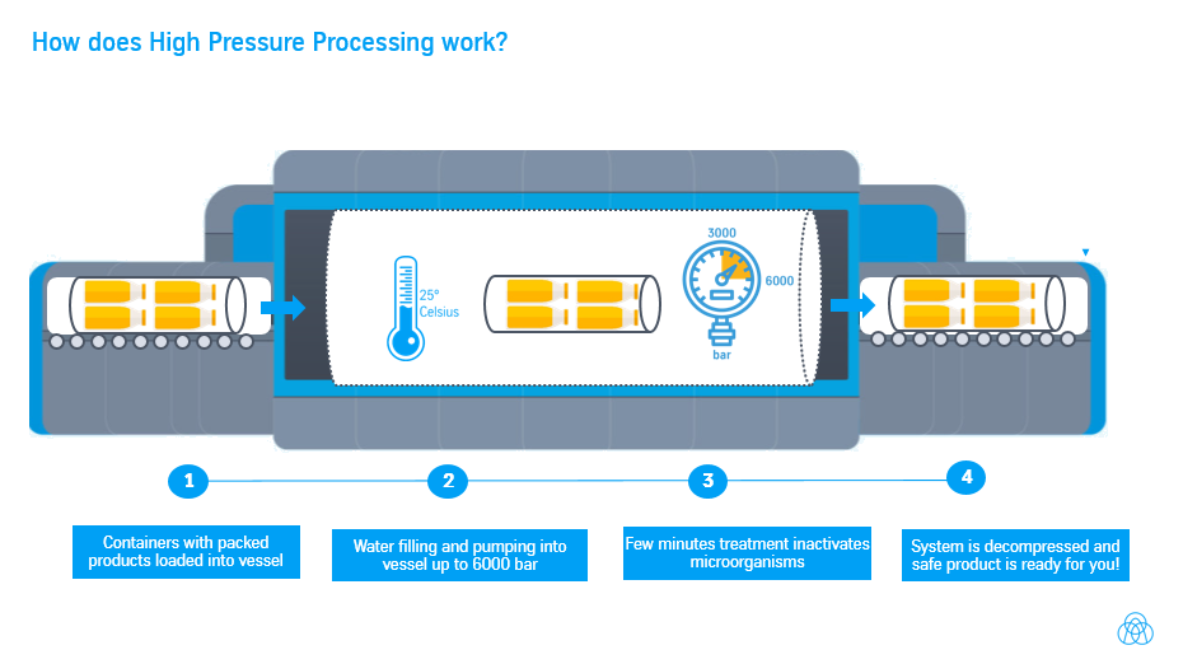

In today’s competitive U.S. beverage market, High-Pressure Processing (HPP) is no longer a premium differentiator—it is a commercial standard for retail‑scale distribution. As the industry’s preferred method for pathogen reduction without heat, HPP enables brands to meet food‑safety requirements while preserving the fresh taste, nutrients, and visual appeal consumers expect.

Yet HPP is unforgiving to packaging. Under extreme pressure cycles, a bottle must perform as a structural system—not merely as a container. Plascene’s rPET Cold‑Press Bottles are purpose‑engineered to withstand these forces, ensuring your premium juice products retain their form, seal, and shelf appeal from production line to final pour.

That is why Plascene’s rPET Coldpress Bottles—a benchmark for HPP‑compatible packaging—are designed to optimize both operational reliability and retail performance.

Engineering for Resilience: Performance Under Pressure

HPP represents a true stress test for packaging integrity. During each processing cycle, bottles compress by approximately 15% in volume before rebounding—an environment that quickly exposes the weaknesses of low‑quality plastics.

-

HPP Resilience: Plascene’s Round Profile distributes pressure evenly across 360 degrees, reducing stress concentration by up to 40% compared to angular designs, effectively eliminating permanent paneling. This geometric advantage ensures that the rPET Coldpress Bottles return to their original shape perfectly once the pressure is released.

- Material Precision: Our rPET is manufactured under strict Intrinsic Viscosity (IV) controls, allowing the bottle to flex without micro‑stress cracking—the root cause of most post‑HPP leakage failures.

-

38mm Tamper-Evident Security: Engineered for absolute reliability, our 38mm TE finish maintains 100% seal integrity. Even under pressures reaching 87,000 psi, the cap remains fully seated, delivering a leakage failure rate below 0.01%. This level of precision makes Plascene’s rPET Cold‑Press Bottles a trusted choice for high‑volume beverage producers.

California SB 54 Compliance: Future‑Proofing Your Supply Chain

As sustainability regulations accelerate across the Western U.S., speed‑to‑market must now align seamlessly with environmental compliance.

- Regulatory-Ready: California SB 54 mandates ambitious recycling and Extended Producer Responsibility (EPR) targets. Plascene goes beyond basic PET compliance, offering customized rPET solutions engineered to meet both your and regulatory requirements today—without operational disruption.

- Domestic Speed Advantage: In B2B beverage manufacturing, proximity matters. With U.S.‑based production, Plascene offers competitive lead time compared to our international competitors. Local sourcing supports sustainability objectives while minimize freight costs and supply‑chain risk.

The Economics of “Clear” Branding: rPET vs. Standard PET

Sustainability does more than build credibility—it drives measurable growth.

-

Visual Parity: Plascene’s rPET delivers glass‑like clarity comparable to virgin PET. Industry surveys indicate that 72% of U.S. consumers associate bottle clarity directly with perceived freshness.

- Built‑In Premium: According to McKinsey research, products making sustainability claims achieve up to 28% higher cumulative growth than non‑sustainable counterparts. Choosing rPET Cold‑Press Bottles positions your brand at the intersection of transparency, trust, and performance, strengthening both consumer loyalty and revenue potential.

Conclusion: The Right rPET Cold‑Press Bottle Is a Competitive Advantage

Selecting Plascene’s rPET Cold‑Press Bottles is more than a packaging decision—it is a strategic investment in reliability, compliance, and premium brand equity. From HPP resilience to regulatory readiness and rapid delivery, we provide the technical confidence and supply‑chain advantage needed to lead the modern juice market.

Contact Us

Plascene Inc,

1600 Pacific Avenue

Oxnard, CA 93033

+1 888-848-6388

info@plascene.com

rPET Plastic for Food-Grade Packaging: How Closed-Loop Sourcing Eliminates Supply Chain Risk

HDPE vs PET: Which Plastic Bottle Material is Right for Your Product?