Index

ToggleStanding Strong at the 2026 Functional Packaging Trends

The year 2026 marks a pivotal shift in the US packaging landscape, particularly on the West Coast. Sustainability is no longer a “nice-to-have” feature – it is a legal mandate. With California’s AB 793 requiring all plastic beverage containers to contain at least 25% post-consumer recycled plastic (rPET) as of early 2025, the enforcement phase is now in full swing. By 2030, this requirement will jump to 50%, making 2026 a critical mid-point for brands to stabilize their post-consumer resin integration strategies.

Additionally, the upcoming SB 54 Baseline Producer Report due in February 2026 is adding significant administrative pressure on brands. We understand that behind these regulations are real concerns about supply chain disruptions and compliance hurdles. We are here to be your strategic partner, turning these challenges into competitive advantages. Our expertise in navigating these legal frameworks ensures your brand avoids the heavy fines associated with non-compliance.

Securing Supply Amidst the “rPET Crunch”

A major trend for 2026 is the race for “Supply Security.” According to reports from NAPCOR, the demand for rPET, a food-grade material, in the U.S. is expected to far exceed domestic collection rates, leading to potential shortages, particularly on the West Coast. For B2B buyers, the priority has shifted from price alone to guaranteed availability.

Plascene addresses this by leveraging a robust global supply network. We ensure that our clients have a stable, high-quality supply of rPET that meets US food safety standards, protecting your production lines from market volatility. This stable supply chain allows our partners to maintain consistent pricing for their end consumers, even when local markets face scarcity.

The Power of PCR Certification and Transparency

Transparency is the new currency in the 2026 market. This is where PCR (Post-Consumer Recycled) certification becomes essential. It serves as verified proof that your packaging truly contributes to a circular economy.

Plascene is committed to providing materials that meet rigorous PCR standards. By partnering with us, you gain the documentation needed to build trust with retailers and end-users, ensuring your products stay on the shelves of major US retailers.

Simplifying Compliance with Technical Data Support

Navigating laws like SB 54 can be daunting, as they require precise data on packaging weight and material composition for annual reporting. Many brands fail compliance audits not because they don’t use recycled materials, but because they lack the granular data to prove it to state regulators.

We believe compliance should be simple. We support our partners by providing comprehensive Technical Data Sheets (TDS) for every order. Having ready-to-use data on hand allows your compliance team to fulfill reporting requirements accurately and efficiently, saving you time and reducing the risk of administrative errors.

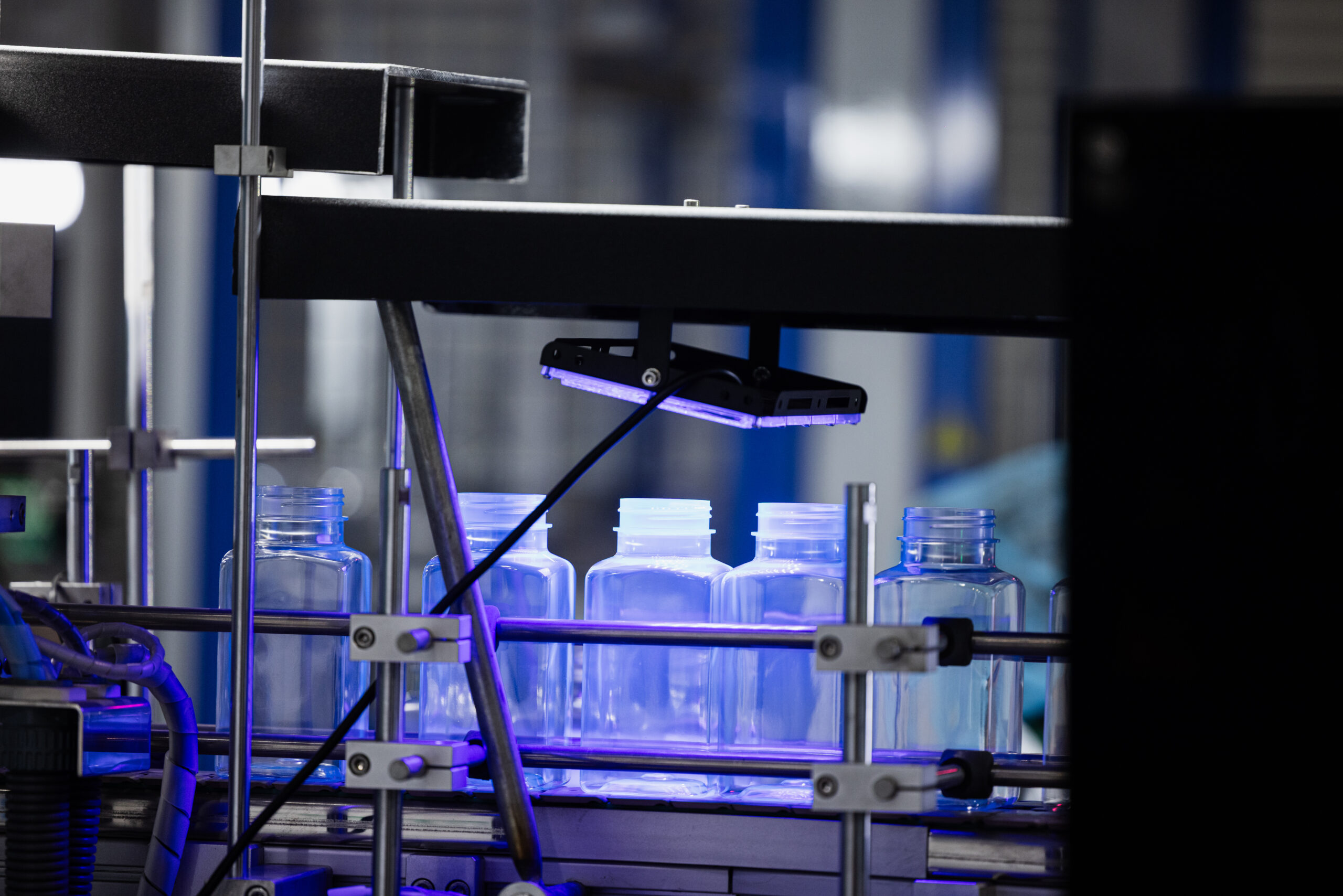

Adaptive Mold Design for an Evolving Market

Consumer demands and labeling regulations are constantly evolving. Whether it is adjusting for new deposit symbols or enhancing ergonomic functionality, having a flexible packaging partner is key. The 2026 consumer prioritizes “easy-to-recycle” designs, meaning that complicated multi-material components are being phased out in favor of mono-material solutions that simplify the waste stream.

Plascene offers expert Custom Mold Design services to help you stay ahead. Our technical team works closely with you to develop functional, attractive, and compliant packaging shapes that resonate with the 2026 US consumer, without the stress of starting from scratch.

Conclusion: 2026 Functional Packaging Trends

Navigating the US packaging market in 2026 requires more than just a supplier – it requires a partner who understands the stakes. From securing your rPET supply to providing the technical data you need for compliance, Plascene is dedicated to your success. Let us help you future-proof your packaging today.

Comment

Contact Us

Plascene Inc,

1600 Pacific Avenue

Oxnard, CA 93033

+1 888-848-6388

info@plascene.com

Other articles

Why Your Strategic Pharmaceutical Plastic Bottle Manufacturer is Key to a Lean Supply Chain in 2026

When sourcing for your brand, choosing the right…

rPET Coldpress Bottles: Maximizing Beverage Sales with HPP-Ready Designs

Ensuring HPP Integrity with rPET Coldpress Bottles

In the…

The Silent Salesman: Why PET Round Straight Wall Jars Drive Your Sales Growth

Beyond the Label: 90% of Decisions Start with Glass-Like…