PET (polyethylene terephthalate) is a clear plastic that is often used to make packaging, such as plastic bottles and food containers. As a packaging material, PET is in high demand because it is transparent, lightweight, shatter resistant, resealable, and--most important of all--recyclable. You can easily identify PET containers because they are stamped with a #1 within a recycling logo, usually on the bottom or side.

Recycled rPET Resin and the Circular Economy

Recycled Resin: Everything Old Is New Again

So what exactly is a "circular economy," and what does it have to do with recycling?

Good question.

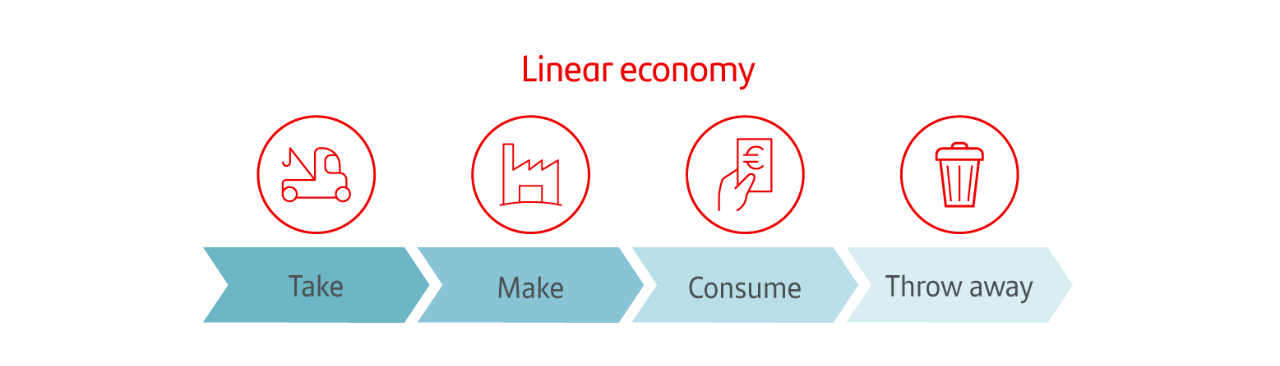

First, consider the way our current linear economy works. We take materials from the Earth, we convert those materials into products, and then we eventually throw them away as waste. This is an economy that sadly favors profit over sustainability.

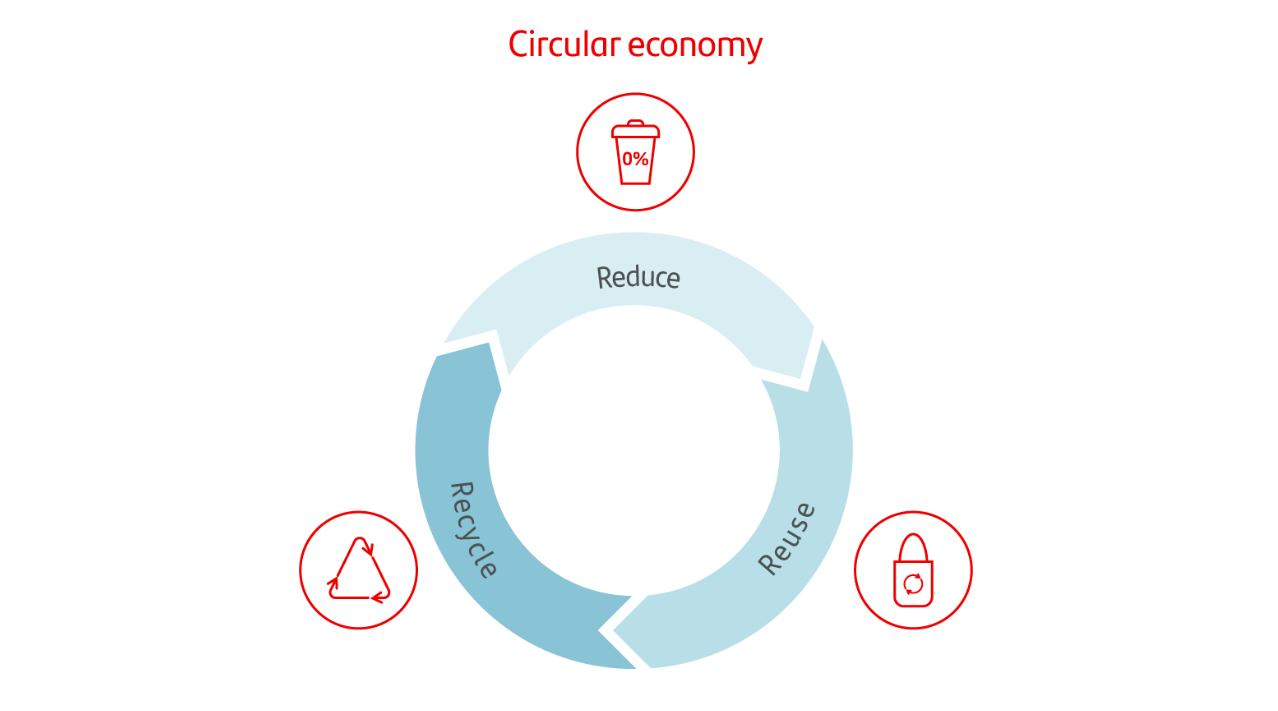

Now imagine a different model where, rather than disposing of used products, we find ways to reuse and recycle them into materials that can then be used to manufacture more products.

Recycling PET into rPET

For the benefit of those who may be new to this site, let's lay down a little vocabulary.

Once the PET containers are used by consumers, they are (hopefully) collected by a recycling program and delivered to a facility like this one. There, the PET plastic is sorted, cleaned, and then transformed into small pellets of rPET (recycled polyethylene terephthalate) resin.

The Challenges of Recycled Resin

As we mentioned, PET is a very durable material. This is both a blessing and a curse, as it makes the plastic ideal for packaging. Unfortunately, it also means that any PET plastic that ends up in a landfill is going to languish there for centuries.

Of course, the idea of a circular economy is to keep the PET plastic out of the landfill altogether. Since PET is 100% recyclable, this basically comes down to educating consumers and improving recycling programs.

Another challenge we face with using rPET resin is that PET plastic cannot be recycled indefinitely. The polymer chains will eventually break down, rendering the rPET unsuitable for plastic bottles. However, even in this state, the rPET resin can still be spun into polyester fiber for carpet, clothing, and filling materials.

However, perhaps the biggest challenge of using rPET resin is simply one of supply vs. demand. In short, there simply isn't enough rPET being manufactured to meet the needs of manufacturers. Again, part of this is down to improper disposal, which sees PET plastic ending up in a trash heap rather than a recycling facility. As more and more people make the effort to recycle, there's hope that this gap between supply and demand will eventually close. In the meantime, manufacturers may find themselves turning to alternative sources—such as recycled polyester textiles and clothing—to make up the difference.

Plascene's rPET Resin Processing and Production

At Plascene, we sincerely believe that sustainability and a circular economy are key to ecological responsibility. Our parent company, Duytan Plastics, has constructed a state-of-the-art plastic recycling plant in Ho Chi Minh City, Vietnam, that repurposes more than 100,000 tons of plastic each year.