One material choice. Thousands of dollars in impact. For procurement managers, selecting between HDPE vs PET isn’t just about the bottle – it’s about protecting your product, your budget, and your brand reputation.

Selecting the right packaging is a high-stakes decision that resonates through your entire supply chain. Choosing the wrong plastic can lead to product degradation, costly leaks, or failure to meet strict regulatory standards like California’s SB 54. While both materials are food-safe and fully recyclable, they offer vastly different performance profiles. This guide breaks down the key technical differences between HDPE bottles vs PET bottles to help you make an informed strategic decision.

Index

ToggleA Quick Overview – What Are HDPE and PET?

Before diving into the technicalities, it is essential to understand the basic identity of these two market-leading polymers.

What is PET Plastic?

Polyethylene Terephthalate, identified by Resin Code #1, is a thermoplastic polymer known for its glass-like transparency and high strength-to-weight ratio. It is the gold standard for beverages and premium personal care products where visual appeal is paramount.

What is HDPE Plastic?

High-Density Polyethylene, identified by Resin Code #2, is a versatile plastic characterized by its toughness and opacity. It is naturally translucent or “milky” and is highly prized for its rugged durability in demanding industrial and pharmaceutical environments.

Head-to-Head Comparison – HDPE vs PET

The choice between these materials often comes down to five critical operational factors:

Durability and Impact Resistance

When comparing HDPE bottles vs PET bottles, HDPE is the undisputed champion of impact resistance. Its “rubbery” molecular structure allows it to absorb shocks during shipping without cracking, making it ideal for heavy industrial liquids. PET, while strong, is more rigid and prone to denting or cracking if dropped under significant weight.

Chemical Resistance

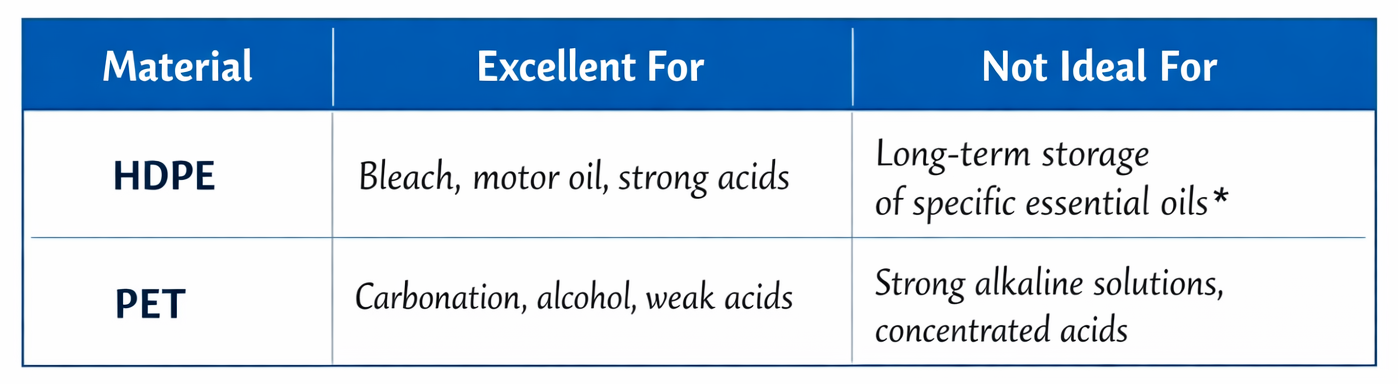

HDPE food safety and chemical stability are world-class. HDPE offers excellent resistance to strong acids and bases. However, selecting the right material depends on your specific formula.

*Note: HDPE is safe for most essential oils; see our specific compati

Transparency and Appearance

PET offers 100% transparency, perfect for showcasing the natural color of juices or lotions. HDPE is naturally opaque, providing an advantage for light-sensitive products that require protection from UV degradation.

Temperature Resistance

HDPE can withstand a wider temperature range, typically from -110°F to 165°F (-79°C to 74°C). PET has a narrower window, usually -40°F to 130°F (-40°C to 54°C). However, for hot fill applications requiring temperatures above 160°F (71°C), specialized heat-set PET bottles are required to prevent deformation. Plascene offers custom heat-set solutions—contact our engineering team for specifications.

Recyclability and Sustainability

Both materials are 100% recyclable. PET plastic sustainability is prominent due to its high recycling rate in the US and ease of processing into food-grade rPET. HDPE is also widely accepted, typically recycled into non-food items like plastic lumber. At Plascene, we offer both virgin and recycled (rPET/rHDPE) options to help brands meet California SB 54 requirements and sustainability goals.

Which Industries Use Which Material?

-

PET Dominates: Beverages (water, soda, juice), food packaging (condiments, honey), and premium personal care.

-

HDPE Dominates: Dairy (milk, yogurt), household cleaners, motor oils, and pharmaceutical packaging.

-

Both Materials: Both are used extensively in essential oil packaging and nutraceuticals.

When to Choose PET – And When to Choose HDPE

Choose PET when:

-

Product visibility and “shelf appeal” are top priorities.

-

Lightweight packaging is needed to reduce shipping costs.

-

The product is acidic or carbonated.

Choose HDPE when:

-

Chemical resistance (e.g., for bleach) and high durability are critical.

-

The product is light-sensitive and requires an opaque barrier.

-

The bottles will face extreme cold or moderate heat.

How Plascene Can Help You Choose the Right Material

Plascene manufactures both HDPE and PET bottles to ensure our clients have the right tool for the job. Our food and beverage containers are all FDA-compliant and manufactured to the highest standards.

Ready to discuss your next project? Contact our team today to get a specialized quote and find the perfect material for your budget and brand.

Comment

Contact Us

Plascene Inc,

1600 Pacific Avenue

Oxnard, CA 93033

+1 888-848-6388

info@plascene.com

Other articles

The Comprehensive Guide to Sourcing Plastic Peanut Butter Jars Wholesale in 2026

In the roadmap of optimizing food supply chains within the…

Plastic Bottles with Caps: 5 Quality Standards in Manufacturing

For procurement managers in the pharmaceutical and food…

Trusted Pharmaceutical Plastic Bottle Manufacturer | FDA Compliant & BPA-Free

Why Material Quality Matters

When sourcing for your brand,…