Index

Toggle6 Tips to Choose the Right Plastic Bottle Manufacturer in the U.S.

When it comes to packaging, choosing the right plastic bottle manufacturer can make or break your product’s success. The bottle is often the first physical touchpoint customers have with your brand – it communicates quality, safety, and even your commitment to sustainability. With so many suppliers in the U.S., how do you know which one is right for your business?

This guide walks you through the key factors to consider, with insights from Plascene, a trusted name in custom plastic packaging that has been serving over 150 U.S. clients for more than a decade.

Why Choosing the Right Manufacturer Matters

Selecting a reliable manufacturer is not just about getting bottles on time—it’s about building a long-term partnership that supports your brand growth. A strong manufacturing partner ensures:

- Consistent product quality

- Compliance with safety and industry standards

- The ability to scale production as your business grows

- Access to design expertise and innovative packaging solutions

Plascene has grown alongside its clients since 2011, offering not just bottles but strategic packaging solutions that help brands expand into new markets.

1. Experience and Industry Expertise

The longer a company has been in business, the more likely it is to understand industry regulations, customer needs, and product challenges. Experience across multiple industries is another advantage—it means the manufacturer can anticipate requirements and adapt quickly.

Plascene was founded in 2011 and has expanded through three major phases of growth. Today, its production capacity exceeds 270 million bottles annually, serving industries such as:

- Food & Beverage (F&B)

- Pharmaceuticals & Nutraceuticals

- Sports Nutrition

- Cosmetics & Personal Care

This multi-sector expertise ensures that Plascene understands diverse compliance standards, from food-grade safety to cosmetic-grade aesthetics.

2. Strict quality standards and certifications

A reliable manufacturer should follow FDA and ISO requirements to ensure products are safe, durable, and compliant with industry standards. It’s also important to understand which plastics are FDA-compliant for food storage, especially if your products are in the food, beverage, or nutraceutical sectors.

Plascene holds ISO 9002 and SQF (Safe Quality Food) certifications, ensuring bottles meet both global safety and quality benchmarks. Their advanced QA system, including Gawis 4D inspection technology, detects even the smallest imperfections, ensuring only top-quality products leave the production line.

For industries like pharmaceuticals or cosmetics, these assurances aren’t optional—they’re mandatory.

3. Custom Plastic Packaging Options

One-size-fits-all packaging rarely works. The right manufacturer should offer custom plastic packaging solutions tailored to your brand identity and functional needs.

Plascene offers both standard PET bottles and custom rPET designs, giving clients flexibility to differentiate their products on the shelf. Their design team stays updated on U.S. market trends, helping brands create packaging that is not only functional but also visually compelling.

Whether you’re launching a new sports drink or a line of organic cosmetics, having a manufacturer that can bring your vision to life is a game-changer.

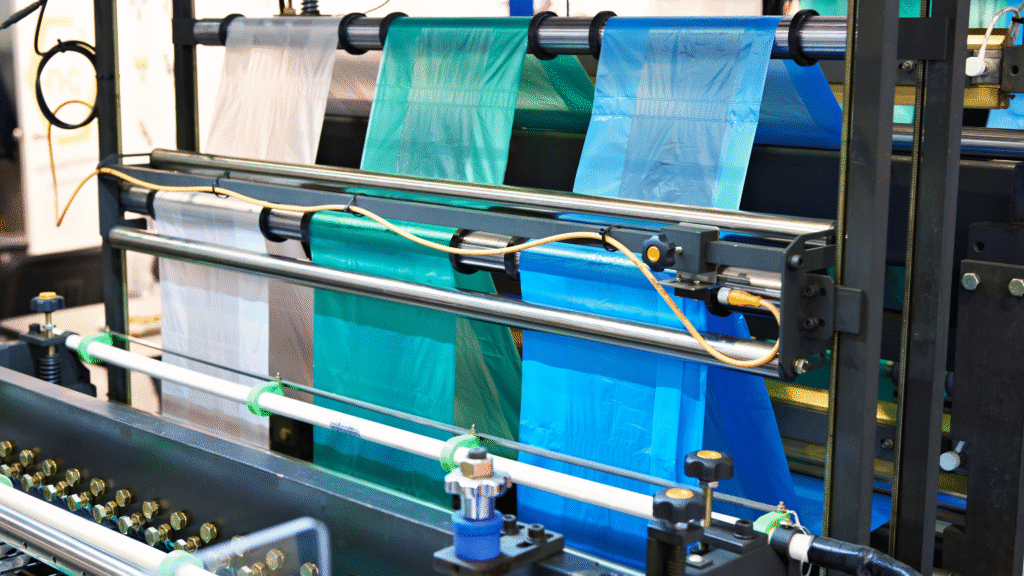

4. Technology and Production Capacity

Cutting-edge technology directly impacts efficiency, consistency, and scalability. If you plan to grow, your manufacturer should be able to scale with you.

Plascene operates with 15 production lines, supported by:

- SAP advanced management system for streamlined operations

- IoT monitoring for real-time efficiency tracking

- Automated QC to remove defective bottles instantly

With a 5,000 m² factory and 8,000 m² warehouse in Oxnard, California, Plascene guarantees not only production capacity but also reliable storage and fast delivery across the U.S.

5. Sustainability Practices

Today’s consumers care deeply about sustainability, and brands are under increasing pressure to minimize their environmental footprint. Partnering with a plastic bottle manufacturer that prioritizes eco-friendly practices is no longer optional.

Plascene is a leader in sustainability with its production of rPET (recycled PET) bottles, which:

- Save 5,774 kWh of energy per ton of recycled plastic

- Reduce landfill waste by 30 cubic yards per ton

- Cut CO₂ emissions by up to 60% compared to virgin plastic

By choosing a cosmetic bottle manufacturer or packaging partner with green practices like Plascene, you align your brand with consumer expectations and industry trends.

6. Customer Support and Reliability

Even the best technology means little without responsive service. A manufacturer should offer clear communication, reliable timelines, and flexibility when challenges arise.

Plascene has built long-term partnerships with brands like Kirkland, REBBL, Trinity Fruit, Robinson Pharma, and Barney Butter. Their philosophy is simple: “Today must be better than yesterday, and tomorrow must be better than today.”

This ongoing commitment to improvement ensures clients always receive better service and higher value over time.

Final Thoughts

Choosing the right plastic bottle manufacturer in the U.S. is about more than cost—it’s about finding a partner who can deliver consistent quality, scalable production, innovative designs, and sustainable solutions that align with your brand’s vision. The right choice will save you time, strengthen your brand image, and ensure your products stand out in a competitive market.

When evaluating potential suppliers, make sure to look closely at:

-

Experience and industry expertise across multiple sectors

-

Strict quality standards and certifications to guarantee compliance and safety

-

Custom plastic packaging options that support your brand identity

-

Advanced technology and scalable production for future growth

-

Sustainability practices that reduce environmental impact

-

Reliable customer support for long-term partnership

With all of these criteria, Plascene stands out as a trusted U.S. manufacturer that doesn’t just meet expectations—it consistently exceeds them. From standard PET bottles to custom cosmetic packaging and eco-friendly rPET solutions, Plascene combines decades of expertise, advanced technology, and a customer-first mindset to help brands grow stronger while building a greener future.

If you’re looking for a plastic bottle manufacturer in the U.S. that goes beyond cost to provide innovation, sustainability, and customer-first service, Plascene is the partner you can count on—helping you stand out with high-quality PET bottles, custom designs, and rPET packaging solutions built for a competitive market.

Recycled PET (rPET): How U.S. Brands Are Meeting State Regulations with Sustainable Bottles

Bullet Bottles for Cosmetics and Personal Care: Design, Safety, and Branding Benefits