Index

ToggleStanding Strong in the 2026 Functional Packaging Landscape

The year 2026 marks a defining inflection point in the U.S. packaging landscape, particularly on the West Coast. Sustainability is no longer a “nice‑to‑have” feature—it is a regulatory imperative. With California’s AB 793 requiring all plastic beverage containers to contain at least 25% post‑consumer recycled plastic (rPET) as of early 2025, the enforcement phase is now in full swing. By 2030, this requirement will increase to 50%, making 2026 a critical midpoint for brands to stabilize and scale their post‑consumer resin integration strategies.

Additionally, the upcoming SB 54 Baseline Producer Report due in February 2026 is intensifying administrative and operational pressure on brands. We recognize that behind these regulations lie real concerns around supply‑chain continuity, reporting accuracy, and compliance risk. Plascene serves as your strategic partner—transforming regulatory complexity into a competitive advantage. Our expertise in navigating evolving legal frameworks ensures your brand remains compliant, protected, and penalty‑free.

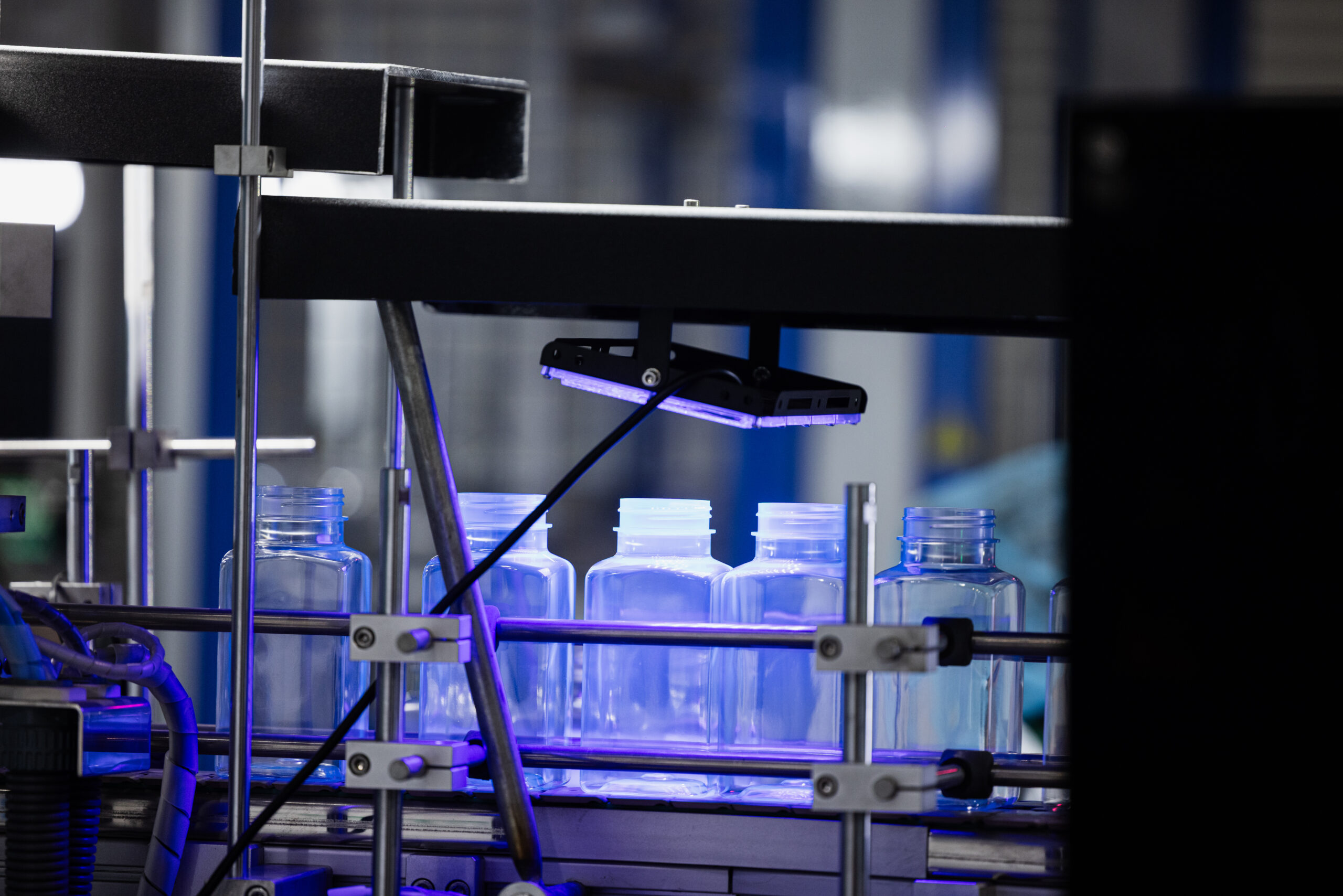

Securing Supply Amid the “rPET Crunch”

A defining trend for 2026 is the race for long‑term supply security. According to NAPCOR, demand for food‑grade rPET in the U.S. is expected to significantly exceed domestic collection rates, creating potential shortages—particularly across the West Coast. As a result, B2B buyers are shifting focus from unit price alone to guaranteed material availability.

Plascene addresses this challenge by leveraging a resilient, globally diversified supply network. We ensure our partners have access to consistent, high‑quality rPET that meets the FDA’s strict standards, safeguarding production lines against market volatility. This stability allows brands to maintain predictable pricing and uninterrupted output, even as regional supply tightens.

The Power of PCR Certification and Radical Transparency

In 2026, transparency is is the currency of trust. This is where PCR (Post‑Consumer Recycled) certification becomes indispensable, serving as verifiable proof of your brand’s contribution to a circular economy.

Plascene is committed to delivering materials that meet rigorous PCR certification standards. By partnering with us, you gain audit‑ready documentation that builds confidence with retailers, regulators, and end consumers—keeping your products approved, credible, and shelf‑ready at major U.S. retailers.

Simplifying Compliance Through Technical Data Excellence

Navigating regulations such as SB 54 can be daunting, as they require precise, defensible data on packaging weight and material composition for annual reporting. Many brands fail audits not because they lack recycled content, but because they cannot substantiate their claims with granular, regulator‑ready data.

At Plascene, we believe compliance should be clear, efficient, and stress‑free. We are always ready to provide comprehensive Technical Data Sheets (TDS) upon request. This ready‑to‑use data enables compliance teams to report accurately, reduce administrative burden, and minimize the risk of costly errors.

Plascene is ready to provide you with complete, audit‑ready technical documentation.

Adaptive Mold Design for an Evolving Market

Consumer expectations and labeling regulations continue to evolve. Whether responding to new deposit symbols or enhancing ergonomic performance, flexibility in packaging design has become a strategic necessity. The 2026 consumer prioritizes easy‑to‑recycle, mono‑material designs, accelerating the phase‑out of complex, multi‑material components.

Plascene offers advanced Custom Mold Design expertise to help brands stay ahead. Our technical team collaborates closely with you to create functional, visually refined, and regulation‑ready packaging that resonates with the 2026 U.S. consumer—without the cost or disruption of starting from scratch.

Conclusion: Leading Through the 2026 Functional Packaging Transition

Navigating the U.S. packaging market in 2026 requires more than a supplier—it demands a partner with foresight and technical authority. From securing your rPET supply to delivering the data and design flexibility required for compliance, Plascene is deeply invested in your long‑term success. Let us help you future‑proof your packaging strategy today.

Contact Us

Plascene Inc,

1600 Pacific Avenue

Oxnard, CA 93033

+1 888-848-6388

info@plascene.com

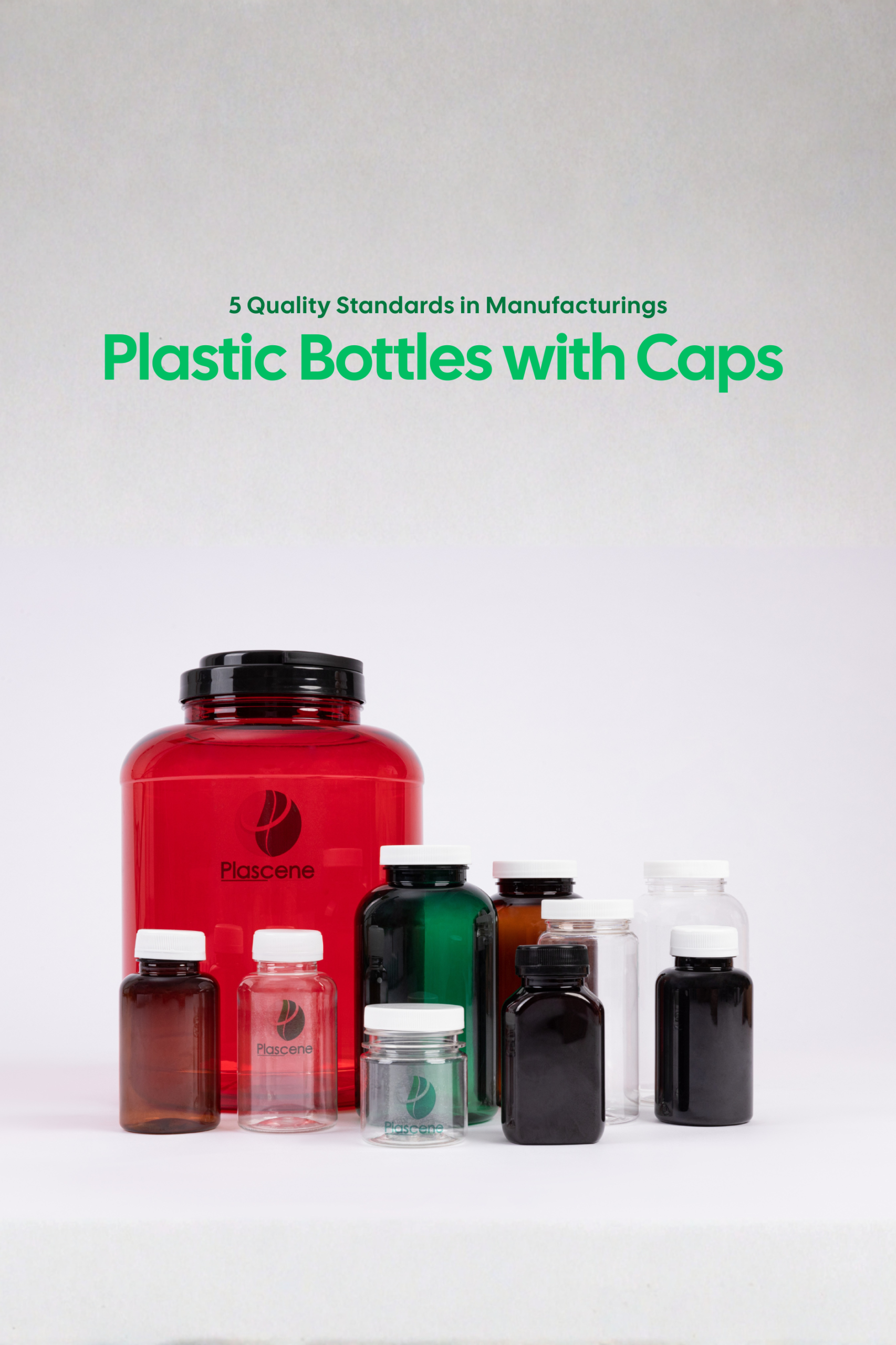

Plastic Bottles with Caps: 5 Quality Standards in Manufacturing

Trusted Pharmaceutical Plastic Bottle Manufacturer | FDA Compliant & BPA-Free